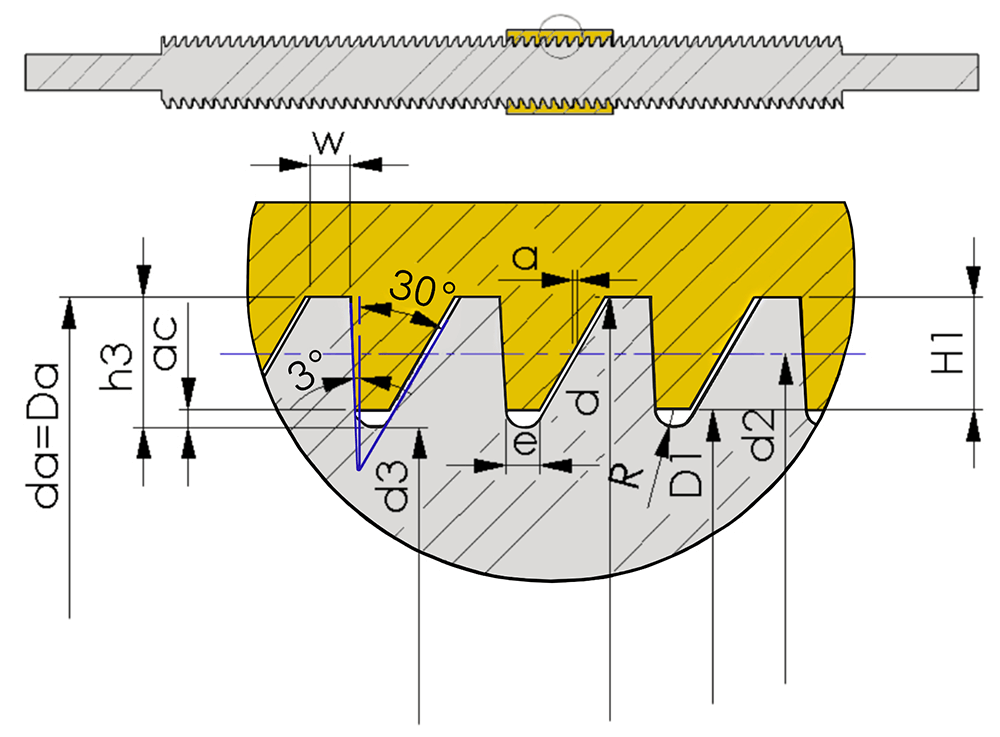

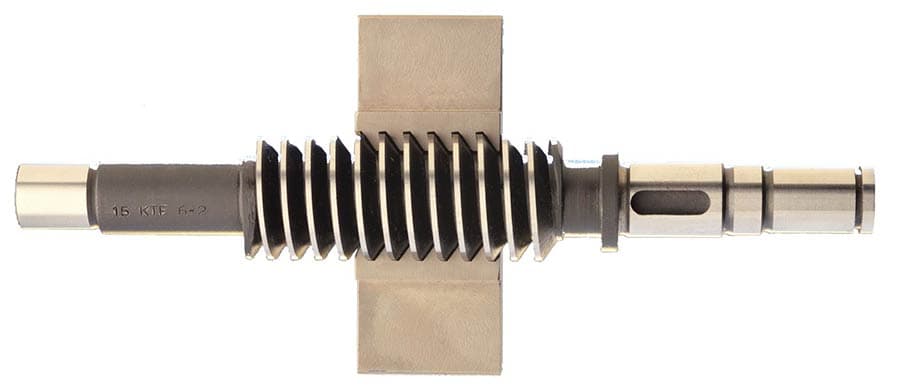

Saw Thread Lead Screws and Nuts

We manufacture your custom-made saw thread lead screws and nuts according to your drawing. Thanks to our innovative and high-quality manufacturing process, micro-pockets are formed on the flank surface, which is ideal for the adhesion of lubricants. As a result, our saw thread spindles have a longer service life and reduced risk of the dreaded stick-slip effect.

Our products – specifications:

| Diameter: |

10-300 mm |

| Length: |

up to 6000 mm standard, up to 22000 mm on request |

| Number of gears: |

1 to 6 standard, from 6 on request |

| End machining: |

according to your drawings |

| Rotation direction: |

RH/LH |

| Materials: |

C45, 42CrMo4, various stainless steels, super duplex, bronze etc. |

| According to standards: |

ISO DIN 513, DIN 20401, DIN 2781 and DIN 6063 |

Send us your technical drawings or specifications.

We would be happy to provide you with a non-binding offer!

Take advantage of our 40+ years of experience in the production of saw thread spindles and nuts made in Germany.

Buttress (Saw) Thread Table with 3D Models – According to DIN 513

Select the right buttress thread size and get a free lead screw 3D model!

Bypass the time-consuming CAD Model design phase by choosing your preferred thread size from our Buttress thread chart and instantly acquire the matching 3D CAD file in your desired format.