Home »

Production and Quality

Production & Quality

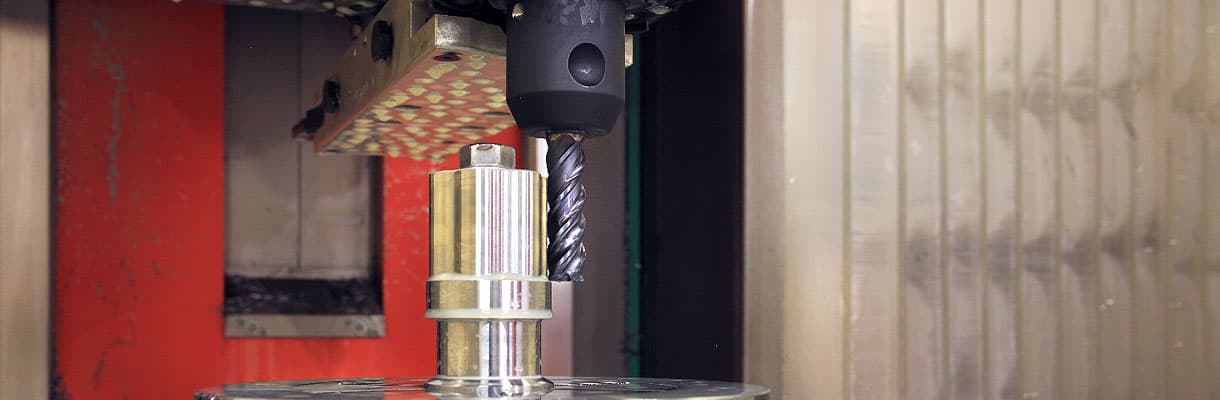

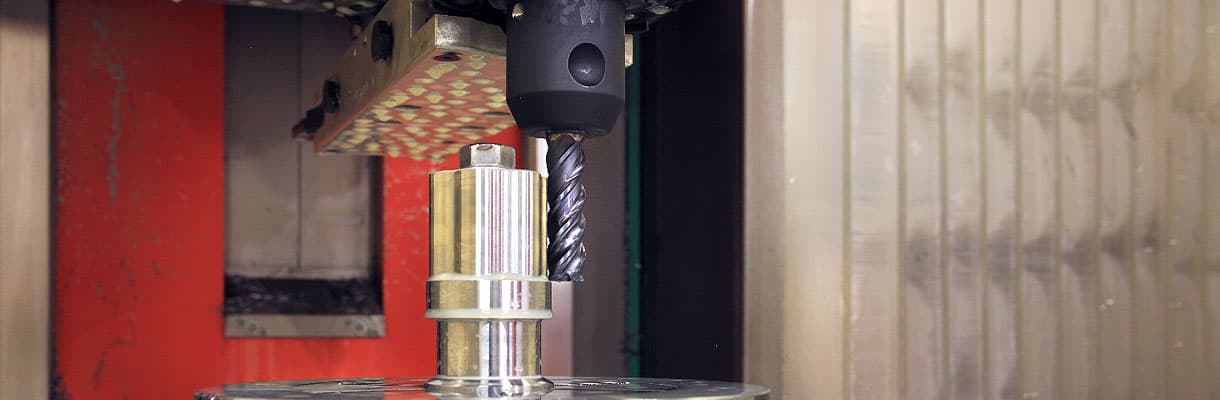

All manufactured parts, from single items to small and mid-sized series, are manufactured according to our clients’ specific instructions. Our advanced machine park with CNC machines – partly designed by our own engineers – 5-axis turn-mill centers, and conventional machines, combined with partially automated production planning thanks to our manufacturing execution system (MES) and a state-of-the-art ERP system, ensure that your orders are carried out quickly and cost-effectively.

Our Manufacturing Range

You can reap the benefits of our streamlined manufacturing processes and extensive vertical range of manufacture. Our portfolio includes the following manufacturing processes and services:

- Thread whirling, milling and cutting

- Conventional turning and milling

- Cylindrical and flat grinding

- Sawing

- Welding

- Truing up to 10 meters

- Cogging

- Surface coating/surface finishing

- Quenching up to a length of 8 meters

Our Range of Services

Our thread production products and services:

- 1, 2, 3, or up to 50-start threads

- Thread lengths of 10 mm to 20 m

- Thread diameters of 10 to 300 mm

- Inner threads of up to 2,000 mm in length

- Complex end machining

- Manufacturing of variable thread pitches (for example for steering shafts)

- Threads made of standard, quenched and special materials (aluminum/special bronze alloys, stainless steel, aluminum, hardened steel, plastics, anti-magnetic steel, titanium, tungsten, etc.)

Thread Whirling

Our main area of expertise is machining whirled internal and external standard and custom-made threads for various high-end mechanical engineering applications. The excellent quality of our threads puts the exceptional quality of our whirling process in a league of its own. This quality makes our whirling processes ideal for producing extremely precise screws requiring an extraordinarily high surface quality that is close to or better than grinding quality. The surfaces generated through the whirling processes also feature very good lubrication adhesiveness, which can greatly reduce the risk of the stick-slip effect.

The thread whirling process is flexible and can be applied to various thread shapes, sizes and lengths, and used with any machinable material. Our in-house production facilities mean we can manufacture the right custom cutting tools to make any special threads you require at very short notice.

Quality Assurance

Consistently accurate, flawless execution

It may be a lofty goal, but we at Bornemann Gewindetechnik pride ourselves on our quality assurance processes and strive for a zero-error strategy. We have made significant investments in this area in recent years. These exemplary QA processes have been recognized and confirmed by our ISO 9001 certification. Partially automated production planning and monitoring processes and our comprehensive ERP system are the cornerstone of our approach. We own a number of effective testing gages, which allows us to provide a complete check even on larger orders.

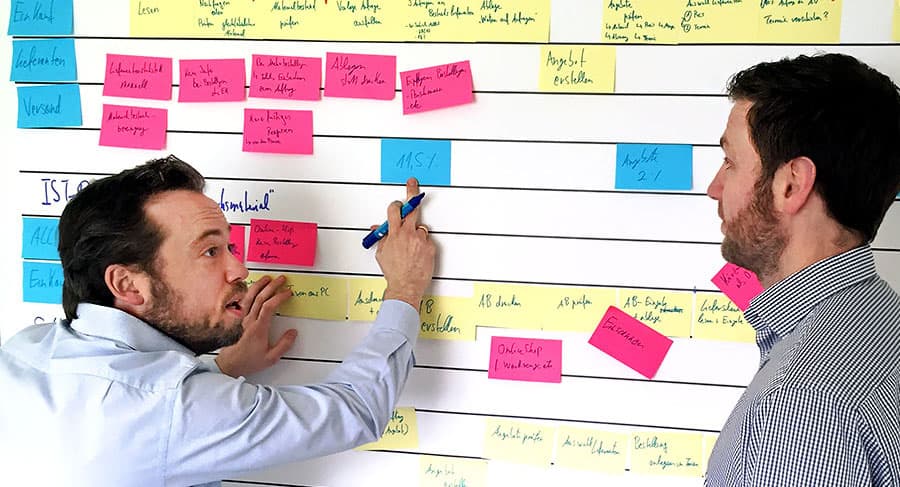

Lean Production

More Than Just a Buzzword

Lean production, put simply, is the process of making production leaner. But the idea behind it is a lot bigger and more in-depth, and has been a key inspiration and driving force behind our activities here at Bornemann Gewindetechnik since 2010.

All of our processes and procedures in all business and production areas are subject to constant analysis and improvement. The typical argument, “But we have always done it this way!” has no place in our business. We encourage all employees to keep an eye out for areas where things could be improved and share their own ideas. This personal commitment is not only valuable – it is also a lot of fun.

But lean production means more to us than pure cost-effectiveness. It also means unleashing the full potential of our single greatest asset: our staff. By respecting the ideas and perspectives each individual employee has to offer, we gain valued insights to help us stay ahead of our competitors and ensure our continued success as a company in the years to come.