Smart Screws – Added Value through Digitisation

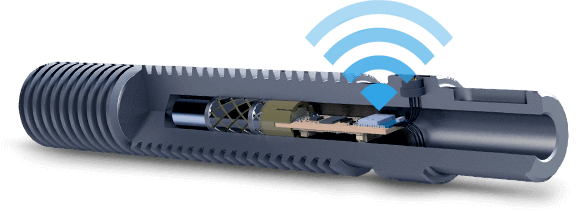

We now develop, design and produce custom smart screw sets with intelligent sensor technology. The integrated sensor technology in our trapezoidal leadscrews records all kinds of interaction between your component and its environment. That means all your measurement data can be recorded, linked, stored and transmitted wirelessly straight from the threaded component thanks to the miniature sensor electronics.

Smart Screw Components: The Benefits at a Glance

The integrated sensors enable you to draw important conclusions and gain in-depth information on the state of your machines and systems. Data logging and on-chip data processing let you store process data and actively control processes based on predefined events through our industry gateway.

Take advantage of the benefits that our smart screws provide:

Overload Protection

The sensors enable you to identify when specific load values are exceeded, allowing you to respond promptly and switch off safety-relevant systems.

Process Monitoring

You can monitor processes in real time, introduce data-based preventative maintenance and continuously optimise the performance of your systems based on the data.

Wear Detection

By detecting changed load profiles, vibrations or changed temperature levels inside your screw components, you can identify wear in good time and implement preventive maintenance strategies.

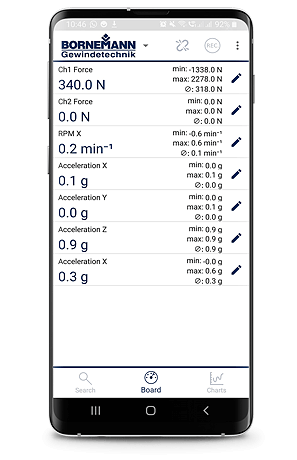

Wireless Transmission of a Multitude of Measurement Data

All the data collected by the smart screw sensors are transmitted to the app and gateway via Bluetooth. That gives you quick and easy access to the measurement values on your smartphone or tablet. Furthermore, the gateway installed in your control cabinet enables the signals to be forwarded to your higher-level measurement systems or controls in analogue or digital form.

How Your Screw Component Itself Becomes a Sensor

The sensors installed inside the thread simultaneously measure the following variables at up to 500 Hz: Axial forces in the tension/compression direction, torsion, RPM, vibrations and the temperature inside the spindle (up to max. 70° C). They open up a multitude of different calculations for the types of load, measurement data collection and comparative analyses, such as:

- For measuring loads, for example

- Lifting systems can weigh goods via lifting screws and identify overloading or load reserves autonomously.

- Cost-intensive load cells can be replaced by inexpensive, safe and smart powerscrews, for instance, in heavy-duty lifting jacks.

- When specific load values are exceeded, actions such as shutting down the lifting jack can be initiated.

- Compare overall load profiles (e.g. in different plants, train depots).

- You can identify where your customer has load reserves and optimise the use of their systems as a result.

- Accuracy, dependent on the geometry and material of the lifting spindle: approx. 1%

- Measuring the breakaway torque of lifting nuts enables you to draw conclusions on the lubricating grease used and the incorrect operation of systems.

- For applications with feedscrews and feedscrew elements, the system can identify various bulk materials based on their density.

- For applications with auger mixers, the system can determine when a defined target viscosity has been reached and actively control the mixing process.

- Monitoring for torque overloads can prevent extrusion systems from failing.

- The inertial measuring unit (IMU) enables the detection of angular acceleration, allowing the travel path of the screw nut to be deduced.

- The most minimal vibrations can be detected, which provides early insights into the degree of wear in the system.

- You can combine the technology with standard temperature profiles to detect the improper handling or installation of systems (for instance, if the system has been exposed to unintended force).

- The temperature profiles detected in a leadscrew allow conclusions to be drawn on the degree of wear in the system. This in turn allows to implement suitable preventive maintenance strategies.

- Pre-defined temperature threshold values can be used to limit the frequency with which a system is used.

A Multitude of Applications in Plant Construction and Mechanical Engineering

We have added smart screws to our portfolio to equip companies involved in plant construction and mechanical engineering to meet the requirements of Industry 4.0. They are intended especially for systems in which threaded spindles or feedscrews are used, such as lifting jack systems, worm gear screw jacks, slide gates, penstocks, machine tools, extrusion technology and dosing and conveying systems.

The threads are extremely versatile and can be used in a multitude of different applications beyond the field of thread technology. Our customers discover new opportunities to use our smart sensor technology in their applications on a daily basis.

Fit for the Future: Make Your Machines and Systems Smart

The new smart threaded components with integrated sensor technology constitute a major step in the path towards digitisation. They make your machines and systems intelligent! Up to this point, the force and torque measuring technology solutions available on the market have had their weaknesses: difficulties with integration, high procurement costs, elaborate measurement chains – hardly the way to embrace Industry 4.0 and its challenges. Smart screw components from Bornemann Gewindetechnik have now solved these problems. They make it easy to meet the requirements of Industry 4.0.

Operate Your Systems in a More Simple, Efficient and Cost-Effective Way

We create custom smart screws for your systems. Thanks to our intelligent thread technology, you can replace external sensors efficiently: Operate your systems in a more simple, cost-effective and safe way. Continuously monitor the state of your systems and detect wear at an early stage – with integrated sensor technology. Mark your company out as an innovator and gain significant advantages over the competition by using smart threaded components!

Can we help you with anything else?

Do you have any questions about our services and the use of smart threads in your company? Call us at +49 (0)5187-9422-0 or send us an e-mail! Our team will be happy to help you.